The container was already booked. We found transit damage at warehouse receiving — and still finished loading on the last night before cut-off.

This shipment was on a fixed schedule — the container had already been booked and the cut-off was close. There was no room for delays.

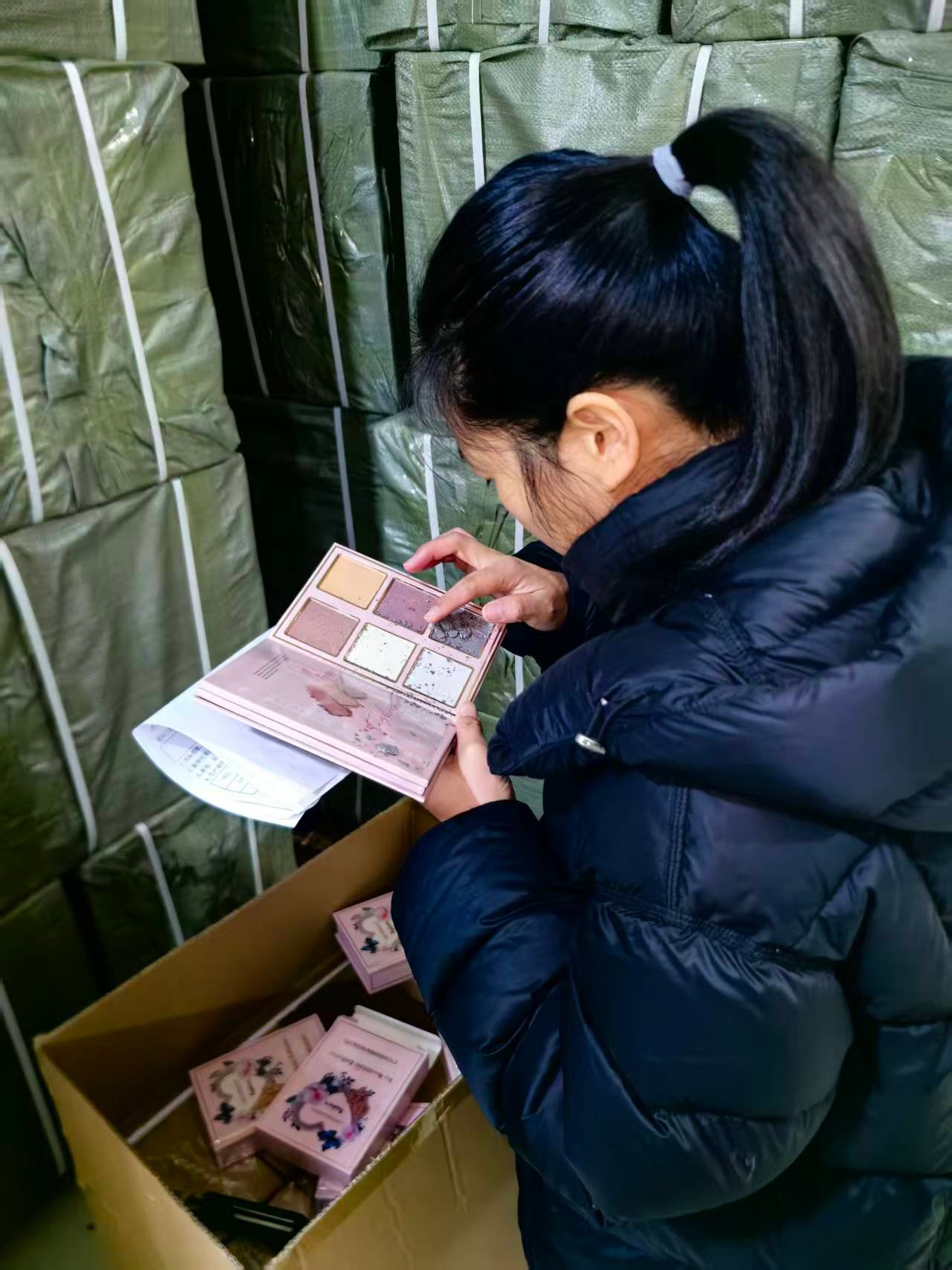

During receiving inspection at our Yiwu warehouse, we found broken pans inside the palettes. The damage happened between the factory and the warehouse — before export.

We isolated the damaged units immediately and recorded quantities. This prevents mixed cartons and avoids hidden problems showing up after arrival.

With the cut-off approaching, I pushed urgent replacement production and prioritized remake. Updates were handled in real time — not the next day.

When the replacement arrived, we re-checked it at the warehouse before it entered the loading line. No assumptions — everything had to match the confirmed standard.

We completed loading that night and sealed the container on schedule. The buyer kept the shipping plan — without shipping broken goods.

The client trusted me more — and stayed. Over 4 years, we grew annual purchasing from $100K → $2.1M+, now shipping 1–2×40HQ/week with 10–30 SKUs per container, fully managed and inspected in China.

Deadlines don’t wait. Problems happen.

What matters is having someone on the ground who can move fast, take responsibility, and keep the schedule.